Product Description

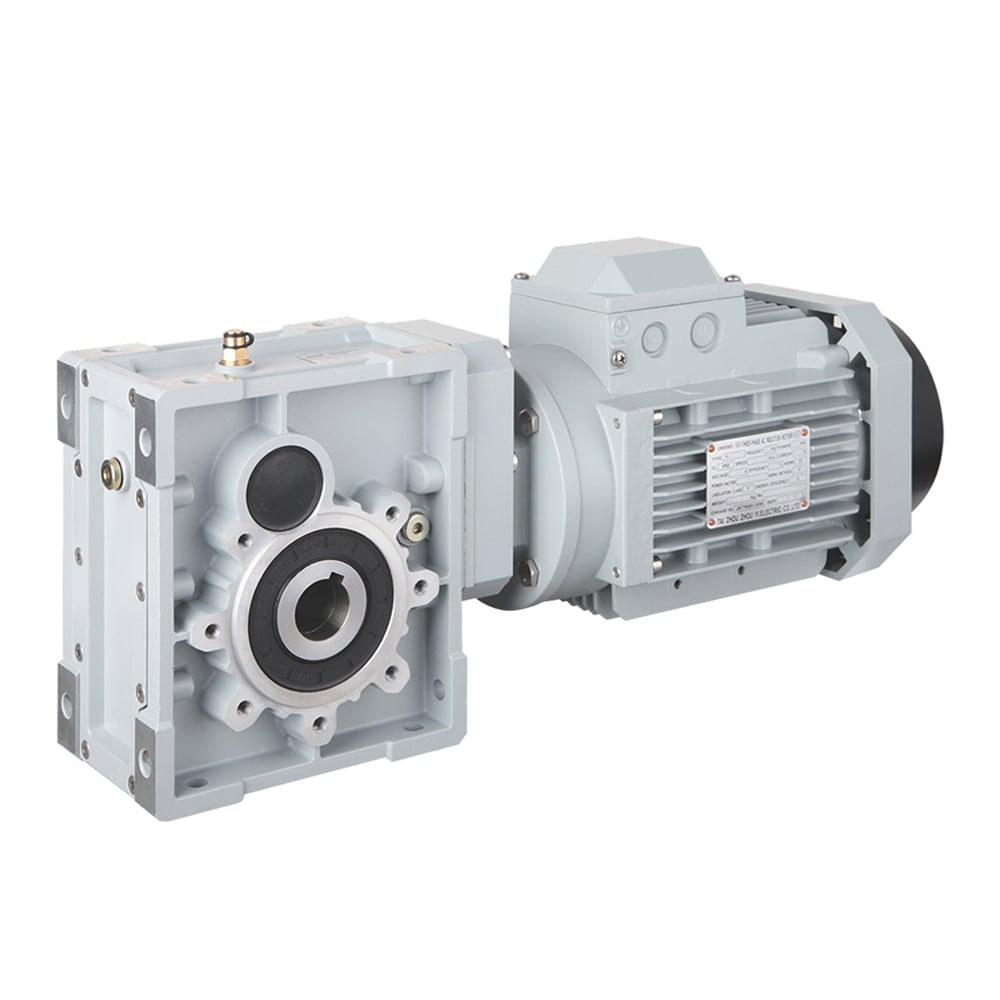

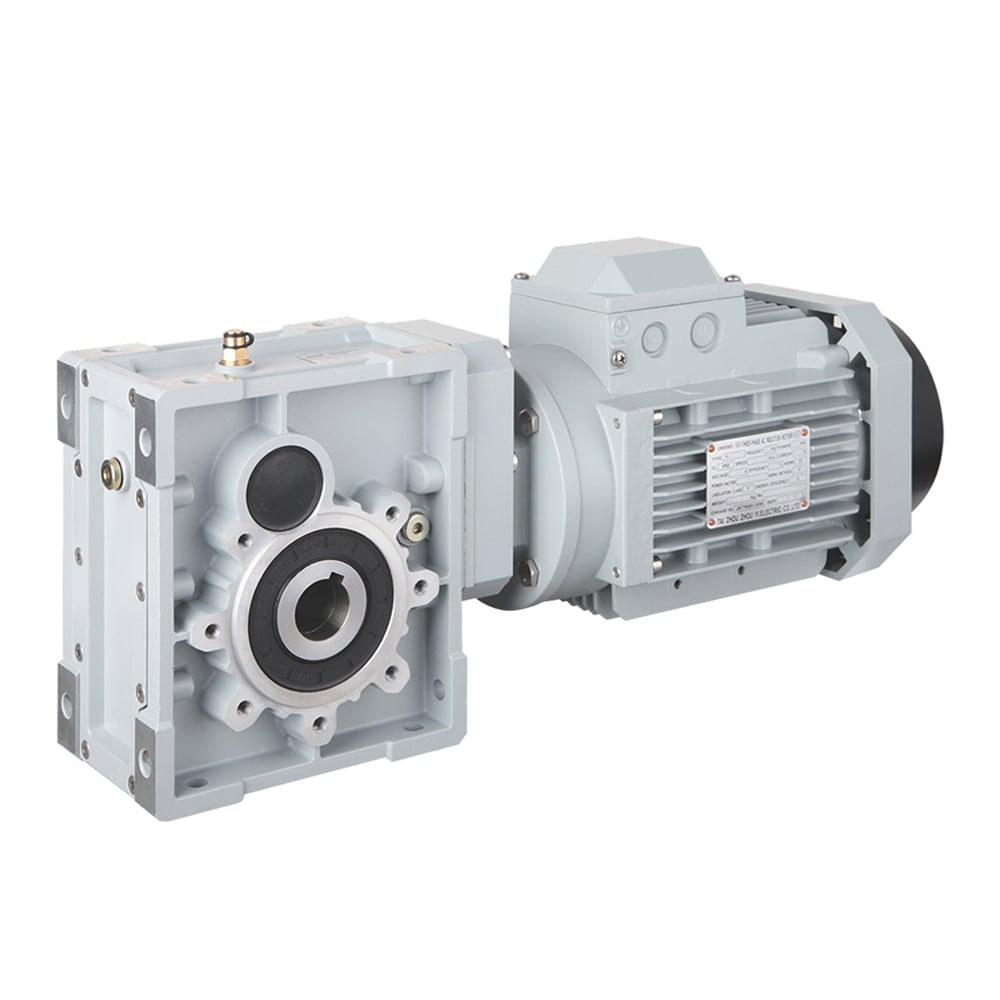

AC Gear Reduction Electric Motor Speed Reducer Motor for agitator mixer

“Bangfeili “brand BH&BV horizontal and vertical gear motor (with the brake) commonly known as reduction motor, is a kind of speed gear motor and motor (motor) the integration of the body. This integration body usually can also be called gear motor, usually assembled by the integration after complete supply by a professional gear reduction motor factory .

The geared motor widely used steel industry, machinery industry, or assembled with magnetic powder clutch and brake , etc. Ac gear motor is generally through the motor, internal combustion engines or other high speed running power through the low rpm ac gear motor input shaft of the less number of gear engagement on the output shaft of big gear to achieve the purpose of the slowdown.

| Parts Name | Parameter | Three Phase Gearmotor | Singel Phase Gearmotor |

| Reducer | Gear Material | High quality alloy steel machined and carburized with precision tooth grinding or skiving. | |

| Housing | Aluminum alloy casting for model 18. 22. 28 . Cast iron for model 40.50 |

||

| Lubrication | High quality #0 lubrication oil (lubricated when shipped) | ||

| Ratio Range | 1/3 to 1/1800 | ||

| Motor | HP | 1/10 HP to 5 HP (75W to 3.7KW) | 1/10HP to 3HP (75W to 2.2KW) |

| Voltage | 208/415, 220/380, 220/440, 230/460, 240/480 | 110/220, 120/240 | |

| Frequency | 50/60HZ | 50/60HZ | |

| Enclose Type | Total Enclosed Fan Cooled, IP54 | Partially Enclosed Fan Cooled | |

| Staring | Full Voltage Drive On Line | Capacitor Start | |

| Housing | Auminum alloy | ||

| Installation | F Grade continuous S1 Duty | ||

| Brake(optional) | Function | Safety Brake | |

| Voltage | DC 90-110V with AC220V Rectifier | DC 90-110V with AC 110V Rectifier | |

| Environmental Specifications | Temperature | “-10ºC-40ºC | |

| Humidity | Under 90% RH (Non-cndensatin) | ||

| Place | Indoor, Below sea level1000m (3.300ft) | ||

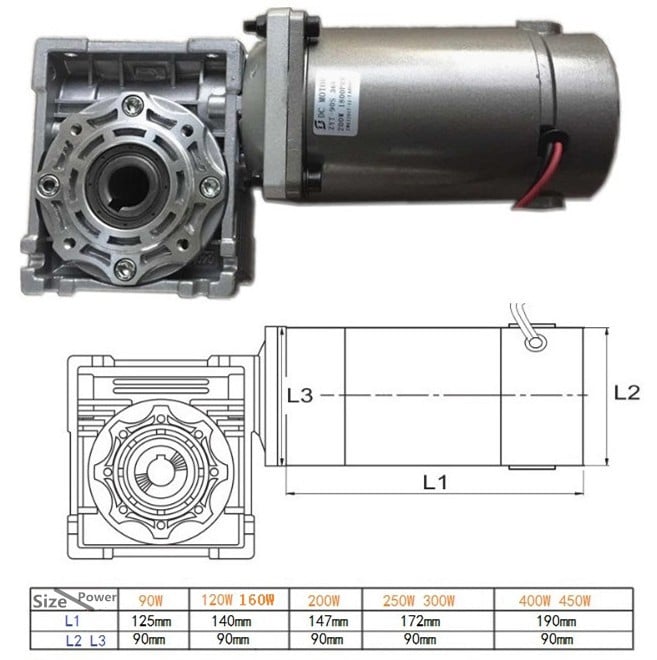

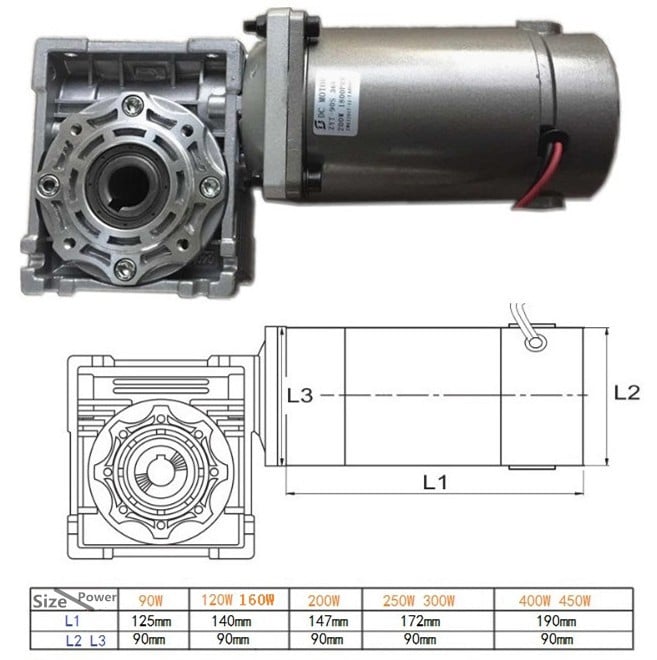

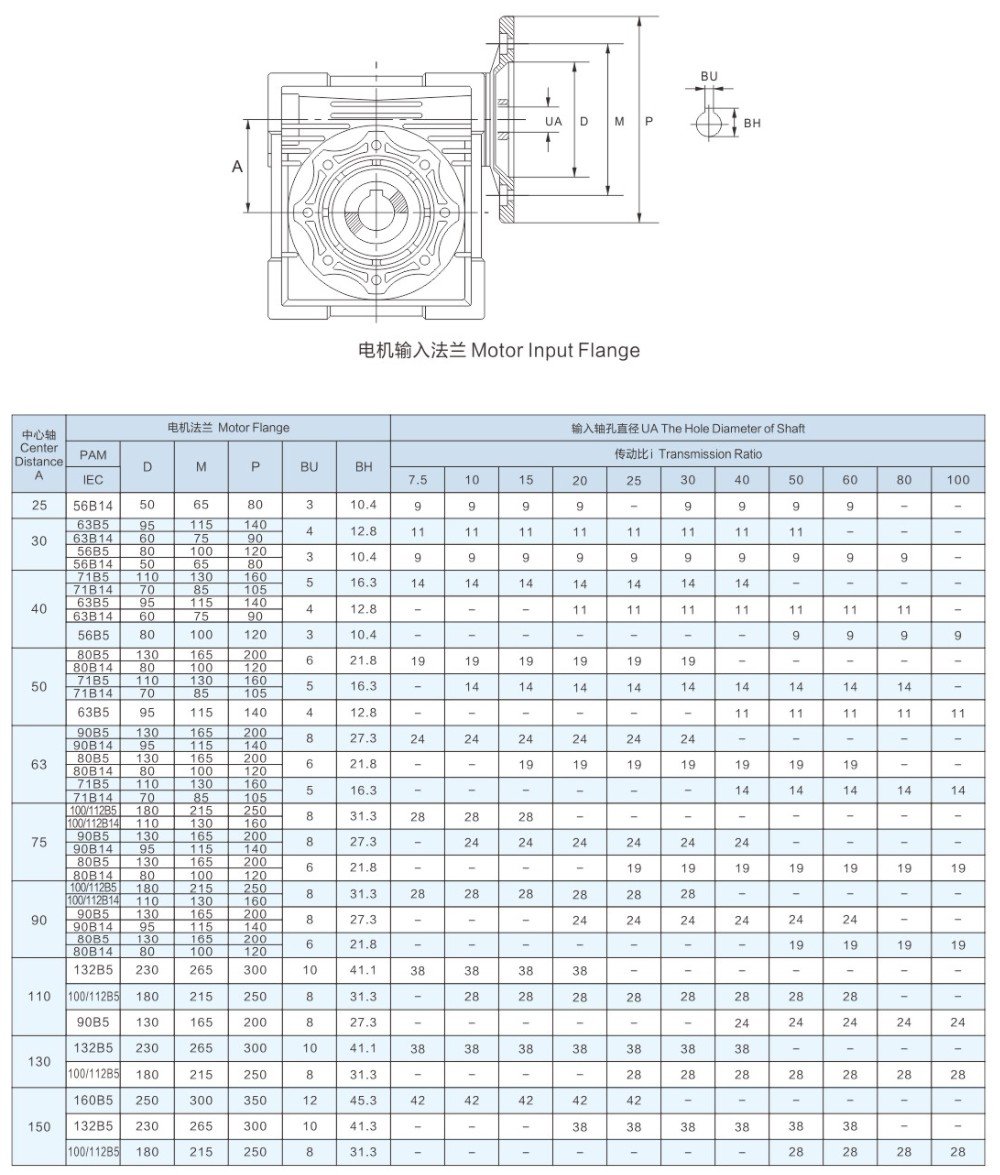

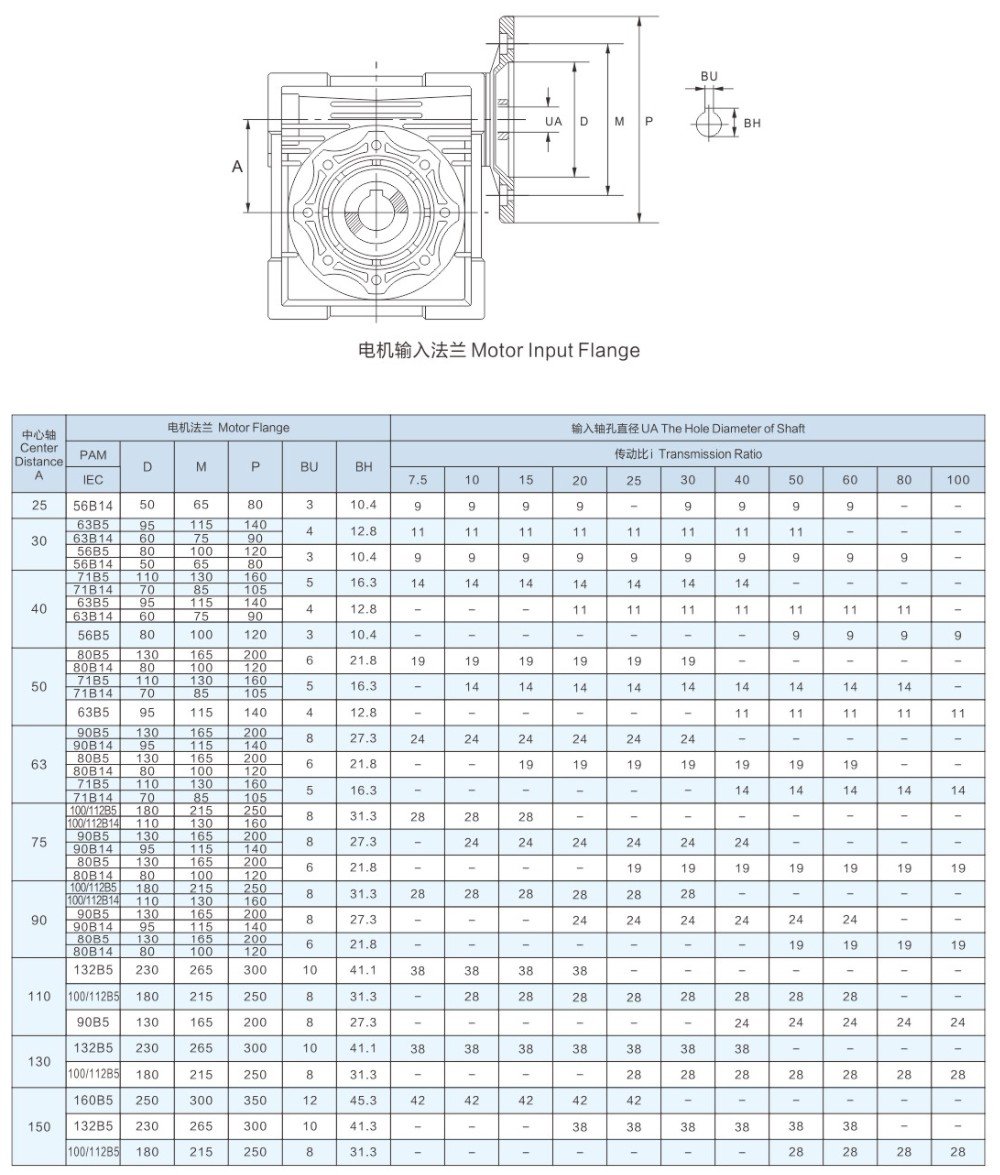

Horizontal & Vertical Reduction Gear Motor Foot

Flange mounting, integrated motor

Output Torque Range: 200 – 15000 Nm

Ratio Range: i = 3-200 i = 250-1800

Power Range: 0.1 – 4KW 1/8HP-5HP

Shaft Size : Ø18-50

100% copper coil is used for each motor

in the outer ring of the worm wheel Cast iron in inner ring

Fine workmanship and durability

ZheJiang Craft ,manufal hand-winding,180 ºC F class

High filling ratio ≥ 95%

Gear precision up to Level 6-5

Each gear has been hobbling, heat treatment, CNC grinding

Each batch of gears have been inspected strictly before storage

Component Flow

Description of Model

FAQ

Q:Are you trading company or manufacture ?

A:We are manu-factory, consist of 3 branch, distributed in East, South and Central of China .

Q: How to choose a gearbox which meets our requirement?

A: You can refer to our catalogue to choose the gearbox or gear motors,or we can help to choose when you provide the technical information ,

such as : Power ,ratio,output torque, output speed and motor parameter etc.

Q: What information shall we give before placing a purchase order?

A: a) Vertical or Horizontal type, ratio, input and output type, input flange, mounting position, and motor information etc.

b) Housing color. c) Purchase quantity. d) Other special requirements.

Q:How long is your delivery time ?what’s your term of payment ?

A:Normally around 2-3 days, the time may vary depending on the order quantity. We accept FOB, CIF price.

Q:How about your paking and export port ?

A:We provide wooden case for machine package.Special requirements is considerable. We support shipping ports: ZheJiang ,Other shipping port is considerable.

Q:What about MOQ?

A:We can accept sample order firstly, so there is no limit for MOQ!

Q:What warranty and after sale service do you offer ?

A:Each product have 1 year(12month) warranty.

| Application: | Industrial |

|---|---|

| Speed: | Variable Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving |

| Casing Protection: | Protection Type |

| Number of Poles: | 2 or 4 or 6 or 8 Pole |

| Customization: |

Available

|

|

|---|

Are there environmental considerations associated with the use of AC motors?

Yes, there are several environmental considerations associated with the use of AC motors. These considerations are primarily related to energy consumption, greenhouse gas emissions, and the disposal of motors at the end of their life cycle. Let’s explore these environmental considerations in detail:

- Energy Efficiency: AC motors can have varying levels of energy efficiency, which directly impacts their environmental impact. Motors with higher efficiency convert a larger percentage of electrical energy into useful mechanical work, resulting in reduced energy consumption. By selecting and using high-efficiency AC motors, energy usage can be minimized, leading to lower greenhouse gas emissions and reduced reliance on fossil fuels for electricity generation.

- Greenhouse Gas Emissions: The electricity consumed by AC motors is often produced by power plants that burn fossil fuels, such as coal, natural gas, or oil. The generation of electricity from these fossil fuels releases greenhouse gases, contributing to climate change. By employing energy-efficient motors and optimizing motor systems, businesses and individuals can reduce their electricity demand, leading to lower greenhouse gas emissions and a smaller carbon footprint.

- Motor Disposal and Recycling: AC motors contain various materials, including metals, plastics, and electrical components. At the end of their life cycle, proper disposal or recycling is important to minimize their environmental impact. Some components, such as copper windings and steel casings, can be recycled, reducing the need for new raw materials and energy-intensive manufacturing processes. It is crucial to follow local regulations and guidelines for the disposal and recycling of motors to prevent environmental pollution and promote resource conservation.

- Manufacturing and Production: The manufacturing and production processes associated with AC motors can have environmental implications. The extraction and processing of raw materials, such as metals and plastics, can result in habitat destruction, energy consumption, and greenhouse gas emissions. Additionally, the manufacturing processes themselves can generate waste and pollutants. Motor manufacturers can mitigate these environmental impacts by adopting sustainable practices, using recycled materials, reducing waste generation, and implementing energy-efficient production methods.

- Life Cycle Assessment: Conducting a life cycle assessment (LCA) of AC motors can provide a holistic view of their environmental impact. An LCA considers the environmental aspects associated with the entire life cycle of the motor, including raw material extraction, manufacturing, transportation, use, and end-of-life disposal or recycling. By analyzing the different stages of the motor’s life cycle, stakeholders can identify opportunities for improvement, such as optimizing energy efficiency, reducing emissions, and implementing sustainable practices.

To address these environmental considerations, governments, organizations, and industry standards bodies have developed regulations and guidelines to promote energy efficiency and reduce the environmental impact of AC motors. These include efficiency standards, labeling programs, and incentives for the use of high-efficiency motors. Additionally, initiatives promoting motor system optimization, such as proper motor sizing, maintenance, and control, can further enhance energy efficiency and minimize environmental impact.

In summary, the environmental considerations associated with the use of AC motors include energy efficiency, greenhouse gas emissions, motor disposal and recycling, manufacturing processes, and life cycle assessment. By prioritizing energy efficiency, proper disposal, recycling, and sustainable manufacturing practices, the environmental impact of AC motors can be minimized, contributing to a more sustainable and environmentally conscious approach to motor usage.

Can AC motors be used in renewable energy systems, such as wind turbines?

Yes, AC motors can be used in renewable energy systems, including wind turbines. In fact, AC motors are commonly employed in various applications within wind turbines due to their numerous advantages. Here’s a detailed explanation:

1. Generator: In a wind turbine system, the AC motor often functions as a generator. As the wind turbine blades rotate, they drive the rotor of the generator, which converts the mechanical energy of the wind into electrical energy. AC generators are commonly used in wind turbines due to their efficiency, reliability, and compatibility with power grid systems.

2. Variable Speed Control: AC motors offer the advantage of variable speed control, which is crucial for wind turbines. The wind speed is variable, and in order to maximize energy capture, the rotor speed needs to be adjusted accordingly. AC motors, when used as generators, can adjust their rotational speed with the changing wind conditions by modifying the frequency and voltage of the output electrical signal.

3. Efficiency: AC motors are known for their high efficiency, which is an important factor in renewable energy systems. Wind turbines aim to convert as much of the wind energy into electrical energy as possible. AC motors, especially those designed for high efficiency, can help maximize the overall energy conversion efficiency of the wind turbine system.

4. Grid Integration: AC motors are well-suited for grid integration in renewable energy systems. The electrical output from the AC generator can be easily synchronized with the grid frequency and voltage, allowing for seamless integration of the wind turbine system with the existing power grid infrastructure. This facilitates the efficient distribution of the generated electricity to consumers.

5. Control and Monitoring: AC motors offer advanced control and monitoring capabilities, which are essential for wind turbine systems. The electrical parameters, such as voltage, frequency, and power output, can be easily monitored and controlled in AC motor-based generators. This allows for real-time monitoring of the wind turbine performance, fault detection, and optimization of the power generation process.

6. Availability and Standardization: AC motors are widely available in various sizes and power ratings, making them readily accessible for wind turbine applications. They are also well-standardized, ensuring compatibility with other system components and facilitating maintenance, repair, and replacement activities.

It’s worth noting that while AC motors are commonly used in wind turbines, there are other types of generators and motor technologies utilized in specific wind turbine designs, such as permanent magnet synchronous generators (PMSGs) or doubly-fed induction generators (DFIGs). These alternatives offer their own advantages and may be preferred in certain wind turbine configurations.

In summary, AC motors can indeed be used in renewable energy systems, including wind turbines. Their efficiency, variable speed control, grid integration capabilities, and advanced control features make them a suitable choice for converting wind energy into electrical energy in a reliable and efficient manner.

Are there different types of AC motors, and what are their specific applications?

Yes, there are different types of AC motors, each with its own design, characteristics, and applications. The main types of AC motors include:

- Induction Motors: Induction motors are the most commonly used type of AC motor. They are robust, reliable, and suitable for a wide range of applications. Induction motors operate based on the principle of electromagnetic induction. They consist of a stator with stator windings and a rotor with short-circuited conductive bars or coils. The rotating magnetic field produced by the stator windings induces currents in the rotor, creating a magnetic field that interacts with the stator field and generates torque. Induction motors are widely used in industries such as manufacturing, HVAC systems, pumps, fans, compressors, and conveyor systems.

- Synchronous Motors: Synchronous motors are another type of AC motor commonly used in applications that require precise speed control. They operate at synchronous speed, which is determined by the frequency of the AC power supply and the number of motor poles. Synchronous motors have a rotor with electromagnets that are magnetized by direct current, allowing the rotor to lock onto the rotating magnetic field of the stator and rotate at the same speed. Synchronous motors are often used in applications such as industrial machinery, generators, compressors, and large HVAC systems.

- Brushless DC Motors: While the name suggests “DC,” brushless DC motors are actually driven by AC power. They utilize electronic commutation instead of mechanical brushes for switching the current in the motor windings. Brushless DC motors offer high efficiency, low maintenance, and precise control over speed and torque. They are commonly used in applications such as electric vehicles, robotics, computer disk drives, aerospace systems, and consumer electronics.

- Universal Motors: Universal motors are versatile motors that can operate on both AC and DC power. They are designed with a wound stator and a commutator rotor. Universal motors offer high starting torque and can achieve high speeds. They are commonly used in applications such as portable power tools, vacuum cleaners, food mixers, and small appliances.

- Shaded Pole Motors: Shaded pole motors are simple and inexpensive AC motors. They have a single-phase stator and a squirrel cage rotor. Shaded pole motors are characterized by low starting torque and relatively low efficiency. Due to their simple design and low cost, they are commonly used in applications such as small fans, refrigeration equipment, and appliances.

These are some of the main types of AC motors, each with its unique features and applications. The selection of an AC motor type depends on factors such as the required torque, speed control requirements, efficiency, cost, and environmental conditions. Understanding the specific characteristics and applications of each type allows for choosing the most suitable motor for a given application.

editor by CX 2023-10-20

China Electric Worm Reducer Motor with Planetary Gearbox with Great quality

Solution Description

Underneath are only some normal designs, for much more specification or a customed motor, pls get in touch with us.

| 24ZYJ DC Worm Gear Motor | |||||

| Basic Data | |||||

| Item | Data | ||||

| Tem Rise | 40K | ||||

| Working Tem | (-20ºC~+80ºC) | ||||

| Insulation Resistance | 100MΩ min 500VDC | ||||

| Surge Examination | 500VAC for 1min | ||||

| Insulation Class | E | ||||

| Weight | 120g | ||||

The specification of Electric worm reducer motor with planetary gearbox

| Specification | |||||||||||

| PN | Rated Voltage | Preliminary Pace | Ratio | Power | Noload Speed | Noload Existing | Rated Speed | Rated Recent | Rated Torque | Stall Torque | Stall Present |

| V DC | rpm | 1:xxx | W | rpm | mA | rpm | mA | Kg.cm | Kg.cm | mA | |

| 24ZYJ4632-65A | twelve | 6500 | a hundred | three | sixty five | eighty | fifty | two hundred | .75 | 2 | one thousand |

| 24ZYJ4632-28A | twelve | 5000 | 180 | three | 28 | 80 | 23 | 200 | one.six | three | one thousand |

| 24ZYJ4632-38A | twelve | 9500 | 250 | three | 38 | one hundred | 33 | 250 | 2.six | 5 | 1500 |

The drawing of Electric worm reducer motor with planetary gearbox

About our firm

Probond motors types brush, brushless, stepper, hysteresis and linear motors to satisfy buyers needs.

Our motors use normal and special parts with consumer selected torque/velocity demands that can be modified to your purposes.

Probond motor owns expert product sales staff and engineer group with more than 10 several years expertise in motor market, primarily based on China mainland managing overseas company for years, we know your requirements much better than other individuals.

Probond Sonicare Toothbrush Motor and Thermostatic Valve Hysteresis Motor are our very hot merchandise on promote in 2017 with highly top quality level and aggressive price tag.

Conditions of Trade

| Terms of price | FOB,CIF,CFR,EXW,DDP,and so on. |

| Terms of payment | one hundred% T/T in advance for samples |

| Bulk quantity payment way can be negotited | |

| Guarantee | 12 months limited warranty once the items are delivered to the buyer. |

| Lead time | Usually within 2 weeks for trial orders, within 3 weeks for bulk orders. |

| Bundle | Carton o plywood pallet. |

| Place of loading | ZheJiang , HangZhou, etc. |

| Shipment carrier | Items are usually shipped via Fedex,DHL, TNT,UPS,EMS for trial orders and via vessel for bulk orders. |

| Delivery time | Usually within 5 working days by Express fifteen-30 working days by vessel |

Our assure to our Buyers:

1. Reply customer’s inquiry in 2 working times.

2. Reply to our client concerns & Worries inside 3 operating times.

three. Admit Consumer purchase orders in 24 hours.

Contact

| Application: | Universal, Industrial, Household Appliances, Car, Power Tools, Beauty Equipments |

|---|---|

| Operating Speed: | High Speed |

| Excitation Mode: | Excited |

| Function: | Control, Driving |

| Casing Protection: | Open Type |

| Number of Poles: | 6 |

###

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| 24ZYJ DC Worm Gear Motor | |||||

| Basic Info | |||||

| Item | Data | ||||

| Tem Rise | 40K | ||||

| Working Tem | (-20ºC~+80ºC) | ||||

| Insulation Resistance | 100MΩ min 500VDC | ||||

| Surge Test | 500VAC for 1min | ||||

| Insulation Class | E | ||||

| Weight | 120g | ||||

###

| Specification | |||||||||||

| PN | Rated Voltage | Initial Speed | Ratio | Power | Noload Speed | Noload Current | Rated Speed | Rated Current | Rated Torque | Stall Torque | Stall Current |

| V DC | rpm | 1:xxx | W | rpm | mA | rpm | mA | Kg.cm | Kg.cm | mA | |

| 24ZYJ4632-65A | 12 | 6500 | 100 | 3 | 65 | 80 | 50 | 200 | 0.75 | 2 | 1000 |

| 24ZYJ4632-28A | 12 | 5000 | 180 | 3 | 28 | 80 | 23 | 200 | 1.6 | 3 | 1000 |

| 24ZYJ4632-38A | 12 | 9500 | 250 | 3 | 38 | 100 | 33 | 250 | 2.6 | 5 | 1500 |

###

| Terms of price | FOB,CIF,CFR,EXW,DDP,etc. |

| Terms of payment | 100% T/T in advance for samples |

| Bulk quantity payment way can be negotited | |

| Warranty | 12 months limited warranty once the items are delivered to the buyer. |

| Lead time | Usually within 2 weeks for trial orders, within 3 weeks for bulk orders. |

| Package | Carton o plywood pallet. |

| Place of loading | Shanghai, Ningbo, etc. |

| Shipment carrier | Items are usually shipped via Fedex,DHL, TNT,UPS,EMS for trial orders and via vessel for bulk orders. |

| Delivery time | Usually within 5 working days by Express 15-30 working days by vessel |

| Application: | Universal, Industrial, Household Appliances, Car, Power Tools, Beauty Equipments |

|---|---|

| Operating Speed: | High Speed |

| Excitation Mode: | Excited |

| Function: | Control, Driving |

| Casing Protection: | Open Type |

| Number of Poles: | 6 |

###

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| 24ZYJ DC Worm Gear Motor | |||||

| Basic Info | |||||

| Item | Data | ||||

| Tem Rise | 40K | ||||

| Working Tem | (-20ºC~+80ºC) | ||||

| Insulation Resistance | 100MΩ min 500VDC | ||||

| Surge Test | 500VAC for 1min | ||||

| Insulation Class | E | ||||

| Weight | 120g | ||||

###

| Specification | |||||||||||

| PN | Rated Voltage | Initial Speed | Ratio | Power | Noload Speed | Noload Current | Rated Speed | Rated Current | Rated Torque | Stall Torque | Stall Current |

| V DC | rpm | 1:xxx | W | rpm | mA | rpm | mA | Kg.cm | Kg.cm | mA | |

| 24ZYJ4632-65A | 12 | 6500 | 100 | 3 | 65 | 80 | 50 | 200 | 0.75 | 2 | 1000 |

| 24ZYJ4632-28A | 12 | 5000 | 180 | 3 | 28 | 80 | 23 | 200 | 1.6 | 3 | 1000 |

| 24ZYJ4632-38A | 12 | 9500 | 250 | 3 | 38 | 100 | 33 | 250 | 2.6 | 5 | 1500 |

###

| Terms of price | FOB,CIF,CFR,EXW,DDP,etc. |

| Terms of payment | 100% T/T in advance for samples |

| Bulk quantity payment way can be negotited | |

| Warranty | 12 months limited warranty once the items are delivered to the buyer. |

| Lead time | Usually within 2 weeks for trial orders, within 3 weeks for bulk orders. |

| Package | Carton o plywood pallet. |

| Place of loading | Shanghai, Ningbo, etc. |

| Shipment carrier | Items are usually shipped via Fedex,DHL, TNT,UPS,EMS for trial orders and via vessel for bulk orders. |

| Delivery time | Usually within 5 working days by Express 15-30 working days by vessel |

How to Assemble a Planetary Motor

A Planetary Motor uses multiple planetary surfaces to produce torque and rotational speed. The planetary system allows for a wide range of gear reductions. Planetary systems are particularly effective in applications where higher torques and torque density are needed. As such, they are a popular choice for electric vehicles and other applications where high-speed mobility is required. Nevertheless, there are many benefits associated with using a planetary motor. Read on to learn more about these motors.

VPLite

If you’re looking to replace the original VP, the VPLite has a similar output shaft as the original. This means that you can mix and match your original gear sets, including the input and output shafts. You can even mix metal inputs with plastic outputs. Moreover, if you decide to replace the gearbox, you can easily disassemble the entire unit and replace it with a new one without losing any output torque.

Compared to a planetary motor, a spur gear motor uses fewer gears and is therefore cheaper to produce. However, the latter isn’t suitable for high-torque applications. The torque produced by a planetary gearmotor is evenly distributed, which makes it ideal for applications that require higher torque. However, you may have to compromise on the torque output if you’re looking for a lightweight option.

The VersaPlanetary Lite gearbox replaces the aluminum ring gear with a 30% glass-filled nylon gear. This gearbox is available in two sizes, which means you can mix and match parts to get a better gear ratio. The VPLite gearbox also has a female 5mm hex output shaft. You can mix and match different gearboxes and planetary gearboxes for maximum efficiency.

VersaPlanetary

The VersaPlanetary is a highly versatile planetary motor that can be mounted in a variety of ways. Its unique design includes a removable shaft coupler system that makes it simple to swap out the motor with another. This planetary motor mounts in any position where a CIM motor mounts. Here’s how to assemble the motor. First, remove the hex output shaft from the VersaPlanetary output stage. Its single ring clip holds it in place. You can use a drill press to drill a hole into the output shaft.

After mounting the gearbox, you can then mount the motor. The mounting hardware included with the VersaPlanetary Planetary Motor comes with four 10-32 threaded holes on a two-inch bolt circle. You can use these holes to mount your VersaPlanetary on a CIM motor or a CIM-compatible motor. Once assembled, the VersaPlanetary gearbox has 72 different gear ratios.

The VersaPlanetary gearbox is interchangeable with regular planetary gearboxes. However, it does require additional parts. You can purchase a gearbox without the motor but you’ll need a pinion. The pinion attaches to the shaft of the motor. The gearbox is very sturdy and durable, so you won’t have to worry about it breaking or wearing out.

Self-centering planetary gears

A planetary motor is a simple mechanical device that rotates around a axis, with the planets moving around the shaft in a radial direction. The planets are positioned so that they mesh with both the sun gear and the output gears. The carrier 48 is flexibly connected to the drive shaft and can move depending on the forces exerted by the planet gears. In this way, the planets can always be in the optimal mesh with the output gears and sun gear.

The first step in developing a planetary gear motor is to identify the number of teeth in each planet. The number of teeth should be an integer. The tooth diameters of the planets should mesh with each other and the ring. Typically, the teeth of one planet must mesh with each other, but the spacing between them must be equal or greater than the other. This can be achieved by considering the tooth count of each planet, as well as the spacing between planets.

A second step is to align the planet gears with the output gears. In a planetary motor, self-centering planetary gears must be aligned with both input and output gears to provide maximum torque. For this to be possible, the planet gears must be connected with the output shaft and the input shaft. Similarly, the output shaft should also be able to align with the input gear.

Encoders

A planetary geared motor is a DC motor with a planetary gearbox. The motor can be used to drive heavy loads and has a ratio of 104:1. The shaft speed is 116rpm when it is unloaded. A planetary gearbox has a low backlash and is often used in applications that need high torque. Planetary Motor encoders can help you keep track of your robot’s position or speed.

They are also able to control motor position and speed with precision. Most of them feature high resolution. A 0.18-degree resolution encoder will give you a minimum of 2000 transitions per rotation between outputs A and B. The encoder is built to industrial standards and has a sturdy gearbox to avoid damage. The encoder’s robust design means it will not stall when the motor reaches its maximum speed.

There are many advantages to a planetary motor encoder. A high-quality one will not lose its position or speed even if it’s subject to shocks. A good quality planetary motor will also last a long time. Planetary motors are great for resale or for your own project. If you’re considering buying a planetary motor, consider this information. It’ll help you decide if a particular model is right for your needs.

Cost

There are several advantages of planetary motors. One of the biggest is their cost, but they can also be used in many different applications. They can be combined with a variety of gearboxes, and are ideal for various types of robots, laboratory automation, and production applications. Planetary gearboxes are available in many different materials, and plastic planetary gearboxes are an economical alternative. Plastic gearboxes reduce noise at higher speeds, and steel input stage gears are available for high torques. A modified lubrication system can help with difficult operating conditions.

In addition to being more durable, planetary motors are much more efficient. They use fewer gears, which lowers the overall cost of production. Depending on the application, a planetary motor can be used to move a heavy object, but is generally less expensive than its counterpart. It is a better choice for situations where the load is relatively low and the motor is not used frequently. If you need a very high torque output, a planetary motor may be the better option.

Planetary gear units are a good choice for applications requiring high precision, high dynamics, and high torque density. They can be designed and built using TwinCAT and TC Motion Designer, and are delivered as complete motor and gear unit assemblies. In a few simple steps, you can calculate the torque required and compare the costs of different planetary gear units. You can then choose the best model for your application. And because planetary gear units are so efficient, they are a great option for high-end industrial applications.

Applications

There are several different applications of the planetary motor. One such application is in motion control. Planetary gearboxes have many benefits, including high torque, low backlash, and torsional stiffness. They also have an extremely compact design, and can be used for a variety of applications, from rack and pinion drives to delta robotics. In many cases, they are less expensive to manufacture and use than other types of motors.

Another application for planetary gear units is in rotary tables. These machines require high precision and low backlash for their precise positioning. Planetary gears are also necessary for noise reduction, which is a common feature in rotary tables. High precision planetary gears can make the height adjustment of OP tables a breeze. And because they are extremely durable and require low noise, they are a great choice for this application. In this case, the planetary gear is matched with an AM8000 series servomotor, which gives a wide range of choices.

The planetary gear transmission is also widely used in helicopters, automobiles, and marine applications. It is more advanced than a countershaft drive, and is capable of higher torque to weight ratios. Other advantages include its compact design and reduced noise. A key concern in the development of this type of transmission is to minimize vibration. If the output of a planetary gear transmission system is loud, the vibration caused by this type of drive system may be too loud for comfort.

editor by czh 2023-01-21

in Bur Sa’id Egypt sales price shop near me near me shop factory supplier Elk 1.5&0.5kw Double Speed Electric Motor End Carriage Driven Motor Geared Reducer manufacturer best Cost Custom Cheap wholesaler

We have exported our merchandise to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the United states of america, Canada, and so on. Much more importantly, we make special elements in accordance to supplied drawings/samples and warmly welcome OEM inquiries. we are self-assured to give our buyers versatile and diversified companies.

ELK one.five amp0.5Kw double speed electric motor finish carriage EPTn motor EPTed EPT

ELK one.5 amp0.5Kw double pace electric powered motor end carriage EPTn motor EPTed EPT breif introduction:

| EPT | cast iron(FC25) substance, large stress, large precision. |

| Equipment | Ni-Cr-Mo alloy steel(SNCM220 ampSCM415) with warmth remedy of EPT carbonitriding. |

| Shaft | alignment and grinding, high accurate, large abrasion and strike resistance, up five instances basic safety factor,EPT provider life. |

| Buffer |

undertake soft commencing and flywheel, make start off and brake steady, sleek and not shake, |

| EPT |

straightforward warmth dissipation, good substantial voltage resistance, minimal sounds, high performance, |

| Electromagnetic brake |

EPT braking force, bolt manage braking power straight, braking pad higher put on |

ELK 1.5 amp0.5Kw double pace electric motor stop carriage EPTn motor EPTed EPT proportions:

ELK one.5 amp0.5Kw double speed electric powered motor stop carriage EPTn motor EPTed EPT Parameters:

| Product | EPT | Quantity of poles | Output EPT Module | Reduction ratio | Rotation pace | Voltage | |

| KD-300 with buffer |

two.2Kw | 4P | M4,M5,M6 | sixteen:1 | 92R/min(50Hz) | 110R/min(60Hz) | two hundred-600V/3Phase |

| one.5Kw | 6P | 61R/min(50Hz) | 73R/min(60Hz) | ||||

| 1.five amp0.5Kw | four/12P | 92/31R/min(50Hz) | one hundred ten amp37R/min(60Hz) | ||||

| KD-three hundred | M3.five | Enamel | 19T | 21T | 23T | 25T | 27T |

Reduction ratio:seven.seven:1 Output shaft:112Rotate |

|

| Speed | 17m/min | 18.8m/min | twenty.5m/min | 22.3m/mim | 24.2m/min | ||||

| M4 | Teeth | 16T | 17T | 18T | 19T | 20T | 21T | ||

| Velocity | 16.5m/min | 17.5m/min | eighteen.6m/min | 19.6m/min | 20.7m/min | 21.7m/min | |||

| M5 | Enamel | 13T | 14T | 15T | 16T | 17T | 18T | ||

| Velocity | sixteen.7m/min | 18m/min | 19.3m/min | 20.6m/min | 21.9m/min | 23.2m/min | |||

| M6 | Teeth | 11T | 12T | 13T | 14T | 15T | |||

| Pace | 17.4m/min | 19m/min | 20.5m/mim | 22.2m/min | 23.7m/min |

ELK one.5 amp0.5Kw double velocity electric powered motor finish carriage EPTn motor EPTed EPT Software:

ELK 1.five amp0.5Kw double velocity electric motor stop carriage EPTn motor EPTed EPT attributes:

Best China manufacturer & factory NMRV110 in Managua Nicaragua with ratio15 worm gearbox worm speed reducer with 15hp 2hp 3hp electric motor With high quality best price

EPG will always adhere to it enterprise spirit of being practical, innovative, efficient and excellent to make the top international transmission drive.

Overview

Quick Details

- EPG is specialized in design, manufacturer and sales of agricultural machinery and farm implements, which has an independent import and export rights. Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- ITEM NO:

-

SYF

- Color:

-

Blue

- Product name:

-

Worm Gear Screw Jack

Share-holding in other manufacturing companies (i.e. EPG and HPT ), trading companies and service companies, as well as significant commercial partnerships, create an ideal distribution of competences enabling higher specialization and extreme rapidity in the management of inquiries. This organisation makes us an all-embracing, versatile and highly skilled supplier in the world of motion drives.

- Material:

-

Aluminium Alloy

- Application:

-

Machine Tool

- Bearing:

-

NSK

- Certificate:

-

ISO9001

- Ratio:

-

5-100

- Mounting Position:

-

Flange Mounted

- Input Form:

-

IEC Flange

Packaging & Delivery

-

Lead Time

: -

Quantity(Pieces) 1 – 500 >500 Est. Time(days) 20 To be negotiated

Online Customization

Product Description

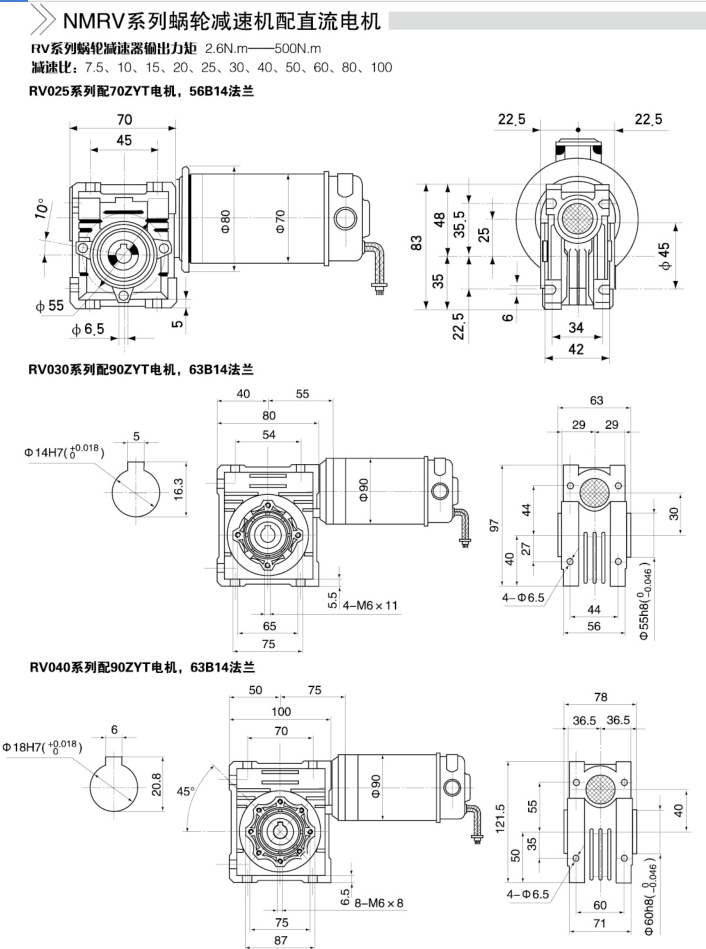

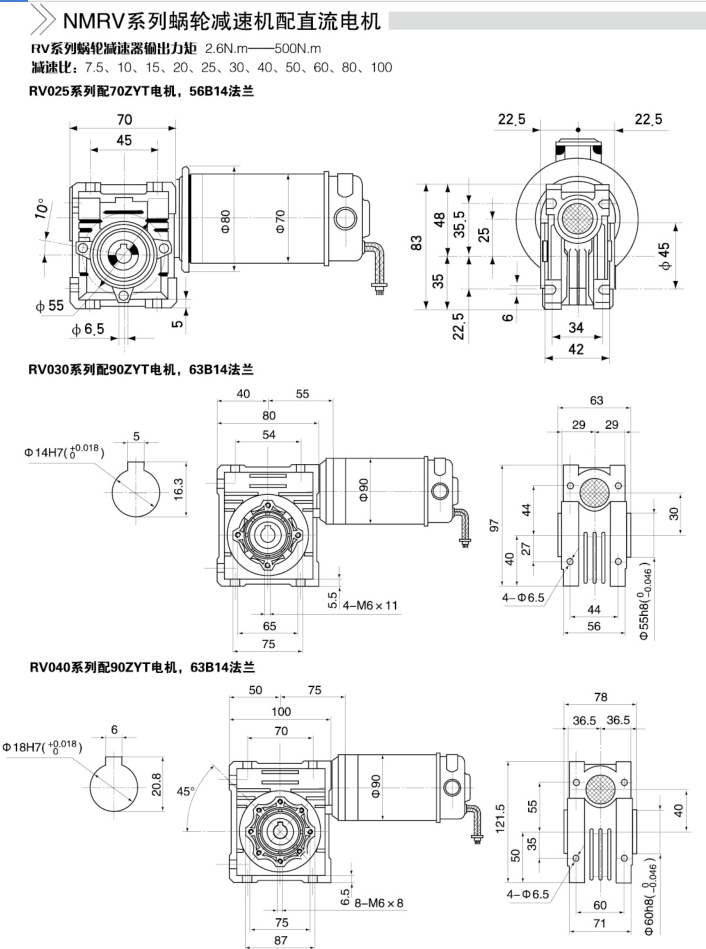

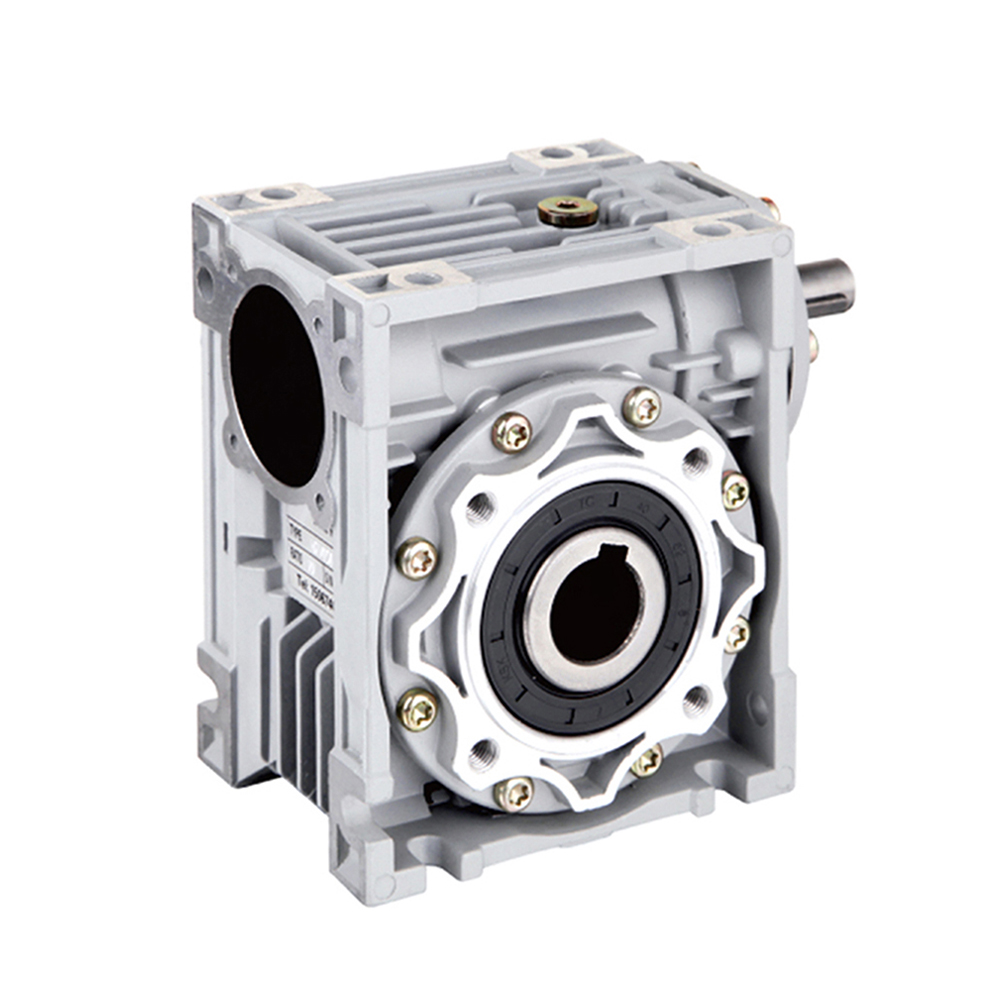

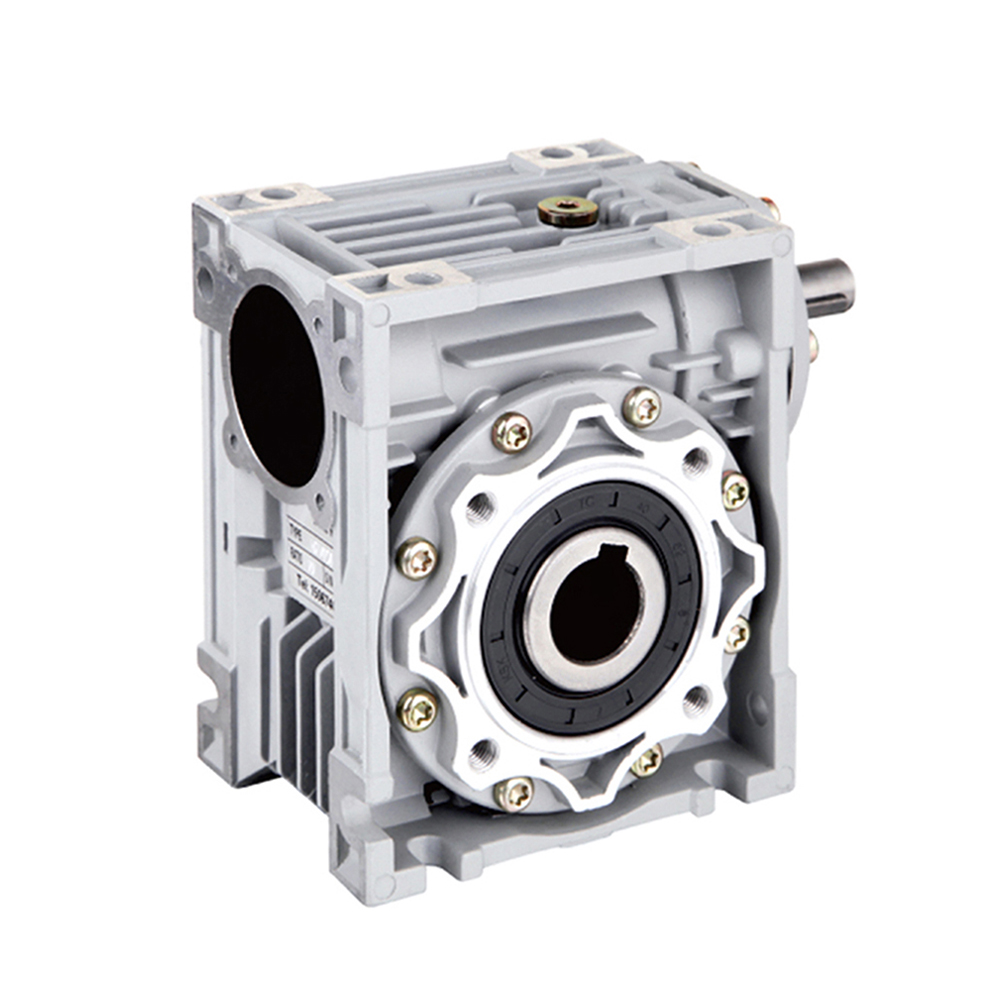

NMRV WORM GEAR SPEED REDUCER WITH ZYT SERIES DC MOTOR

According to European standard of similar product,we adopt high-quality artificial oil,imported famous brand seal parts and manufacture technology to produce square multi-placed reductor. Feature beautiful appearance,easy installation,compact structure,low noise and high efficiency.

NMRV worm gear reducer absorbs advanced technology at home and abroad. It has a novel and unique “square box” external structure. The box is beautiful in shape and is made of high quality aluminium alloy by die casting.

NMRV series structure drawing

|

Worm Gear Speed Reducer NMRV+DC Motor Hot Selling Point |

||

|

Selling point 1 |

The main feature is that it has reverse self-locking function, Suitable for all-round installation. |

|

|

Selling point 2 |

Small size, light weight, low noise, long service life. |

|

|

Selling point 3 |

Using high quality materials, high quality heat treatment. |

|

|

Selling point 4 |

We can customize the motor parameters according to the customer’s requirements. |

|

|

Selling point 5 |

We will provide the best after-sales service. |

|

|

Selling point 5 |

ZYT series permanent magnet DC motors, with the improvement of people’s living standards and the development of modern production and office automation, household appliances, industrial robots and other equipment are becoming more and more rate-oriented, miniaturized and intelligent. As an important part of the executive components, the motor must have the characteristics of high precision, high speed and high efficiency. The application of DC brushless motors is also due to the fact that This has led to rapid growth. |

|

NMRV NRV SERIES WORM GEAR SPEED REDUCER MOUNTING DIMENSIONS

PRECISION BEVEL GEAR

20CrMn Ti material – low carbon alloy steel

Imported gear grinding machine processing, high hardness, stable performance.

Vacuum furnace carburizing heat treatment, carburizing layer uniform.

HIGH QUALITY SHELL MATERIAL

The box body is made of HT200 material,which is cleaned by professional screening and washing equipment to ensure that the inner cavity of the box body is cleaner without iron filings.

HIGH QUALITY OUTPUT SHAFT

New standard axle, multi-precision machining, through rigorous dynamic and static balance test, to ensure low noise and smooth operation of reducer

Shear bolt torque limiter (SB) EPG GROUP offers high quality PTO shafts with tubes fixed by spring pin, cross joints with roller bearings with rollers

Company Profie

Our company is a famous manufacturer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in china.

We have exported many products to our customers all over the world, we have long-time experience and strong technology support.

Some of our customer :

Italy: GB GEABOX, SATI, CHIARAVALLI, AMA, Brevini

Germany: SILOKING ,GKN ,KTS

France: Itfran, Sedies, Kuhn

Brazil: AEMCO ,STU

USA: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODS

Canada: JAY-LOR , CANIMEX ,RingBall

……

-> Our Company with over twelve year’s history and 1000 workers and 20 sales.

-> With over 100 Million USD sales in 2017

-> With advance machinery equipments

-> With large work capacity and high quality control, ISO certified.

Exhibition

Certifications

FAQ

Q: Are you trading company or manufacturer ?

A: Our group consists in 3 factories and 2 abroad sales corporations.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization. For standard products, the payment is: 30% T/T in advance ,balance before shippment.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please contact us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.

Packing & Delivery