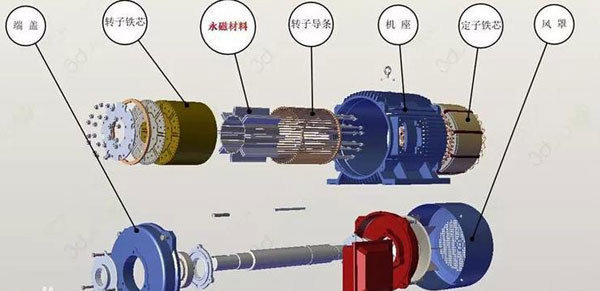

The working principle of the permanent magnet synchronous motor is the same as that of the electric excitation synchronous motor, but the magnetic flux provided by the permanent magnet replaces the excitation winding excitation of the latter, which makes the structure of the motor simpler.

In recent years, the improvement of the performance of permanent magnet materials and the advancement of power electronic technology have promoted the development of new principles and new structures of permanent magnet synchronous motors, and effectively promoted the development, variety and function of motor products.

Some permanent magnet synchronous motors have formed a series of products, their capacity has reached the megawatt level from small to large, and the application range is becoming wider and wider; from military to civilian use, from special to general rapid expansion, its status has become More and more important, not only has advantages in micro-motors, but also shows strong vitality in electric propulsion systems.

1.advantage

Permanent magnet synchronous motor adopts permanent magnet excitation, which has unparalleled advantages of electric excitation motor.

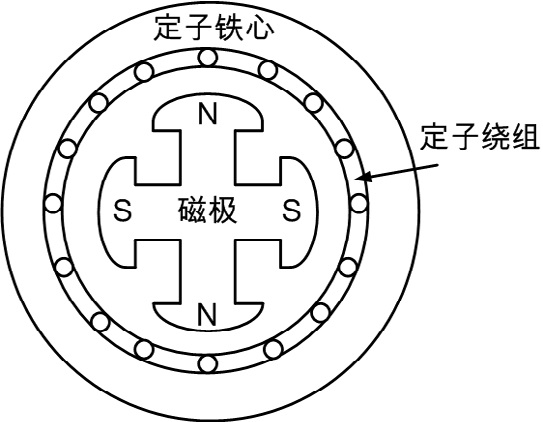

1 High efficiency: The permanent magnet material is built into the rotor, and the rotor and stator magnetic fields operate synchronously during normal operation. There is no induced current in the rotor winding, and there is no rotor resistance and hysteresis loss, thus improving the efficiency of the motor.

2 High power factor: There is no induced current excitation in the rotor of the permanent magnet synchronous motor, and the stator winding presents a resistive load.The power factor of the motor is close to 1, which reduces the stator current and improves the efficiency of the motor.

At the same time, the improvement of the power factor improves the quality factor of the power grid, reduces the loss of power transmission and transformation lines, and can also reduce the power transmission and transformation capacity and save power grid investment. n

3 Large starting torque: In equipment that requires large starting torque, such as oil field pumping units, a permanent magnet motor with a smaller capacity can be used instead of a Y series motor with a larger capacity.

If a 37kw permanent magnet synchronous motor is used to replace the 45kW~55kW Y series motor, the phenomenon of large carriages can be better solved, equipment investment costs can be saved, and the operating efficiency of the system can be improved.

4 Good power performance indicators: when the Y series motors work under 60% load, the efficiency drops by 15%, the power factor drops by 30%, and the power performance indicators drop by 40%; while the efficiency and power factor of permanent magnet synchronous motors drop very much. less.

When the motor has only 20% of the load, its power index still exceeds 80% of the full load.

5 Low temperature rise: There is no resistance loss in the rotor winding, and there is almost no reactive current in the stator winding, so the temperature rise of the motor is low.

6Small size, light weight and less consumables: less volume, weight and materials, the number of permanent magnet synchronous motors with the same capacity can be reduced by about 30%.

7 The armature response is small, and the anti-overload ability is strong.

# ## my country attaches great importance to the research and development of neodymium iron boron permanent magnet motors, and has been included in the national 863 research plan.

After years of research and development, fruitful results have been achieved. 5 types of 22 high-performance permanent magnet synchronous motor prototypes have been developed.

The prototype of the permanent magnet synchronous motor with typical specifications and high efficiency and high starting torque successfully solved the four problems of high starting torque, good energy saving effect, no demagnetization at high temperature, and reasonable cost.

The contradiction of restrictions.Table 1 shows the performance comparison of 37 kW rare earth permanent magnet synchronous motors and induction motors developed by China for oilfield pumping units.

Compared with existing motors, the power factor, efficiency and maximum torque multiples of the developed motors have been improved to varying degrees.The out-of-step torque is 3.59 times the original torque, and the pulling torque is increased by 3 times.

The speed range of the developed permanent magnet synchronous motor speed control system is 0.4r/rain~9000r/min.The speed range of the domestic spindle induction motor of the same specification is only 8r/min~8000r/re e_in, and the constant power speed regulation ratio reaches 1:6.

2.2 Existing problems

#In the process of developing high-performance permanent magnet synchronous motors, while achieving the above results, we also encountered some problems, which need to be further studied and resolved.

1 Irreversible demagnetization problem.

If the design or use is improper, when the temperature of the NdFeB permanent magnet is too high or the temperature of the ferrite permanent magnet is too low, a permanent magnet synchronous motor may be generated under the action of the armature reaction caused by the inrush current, or when the mechanical vibration is severe Time

Irreversible demagnetization or magnetization loss will reduce the performance of the motor, or even make it unusable.

Therefore, it is necessary to conduct research and development of methods and equipment suitable for motor manufacturers to check the thermal stability of permanent magnet materials and analyze the anti-demagnetization ability of various structural types in order to take appropriate measures to ensure that electromagnetic synchronous motors are not Will lose magnetism.

2 Cost issues.

Due to the structure of the ferrite permanent magnet synchronous motor

The process is simple, the quality is reduced, and the total cost is generally lower than that of an electric excitation motor, so it has been widely used.

Because the price of rare earth permanent magnets is still relatively expensive, the cost of rare earth permanent magnet motors is usually higher than that of electric excitation motors, which needs to be compensated by its high performance and reduced operating costs.

In the design, performance and price comparison should be selected according to specific use occasions and requirements, and structural process innovation and design optimization must be carried out to reduce costs.

# ## 3 control issues.

The permanent magnet synchronous motor does not require external energy to maintain its magnetic field, but this also makes it extremely difficult to adjust and control the magnetic field from the outside.

However, with the development of power electronic equipment and control technologies such as MOSFET and IGBT, most permanent magnet synchronous motors can only be used for armature control, but there is no magnetic field control in the application.The design needs to combine the three new technologies of permanent magnet materials, power electronic equipment and microcomputer control, so that the permanent magnet synchronous motor can run under brand-new working conditions.

In addition, the permanent magnet synchronous motor with permanent magnet synchronous motor as the actuator, because the permanent magnet synchronous motor itself is a certain nonlinear, strong coupling and time-varying system, its servo object also has strong uncertainty and nonlinearity. And the system is susceptible to varying degrees of interference during operation.Therefore, advanced control strategies and advanced control system implementation methods (such as DSP-based control) are used to improve the overall level of system intelligence and digitization.This should be a major breakthrough in the current development of high-performance permanent magnet synchronous motor servo systems.